Two projects about wind loading:

- Antenna wind loading

- Advertising fin for car mounting

Antenna wind loading

This particularly challenging problem utilized newly designed and fabricated outdoor dipole antennas where the customer needed to know the wind loading capability of the new product.

The complex multi-layered construction of the antenna means that an alternate method is needed to establish the assembled material parameters. An innovative simply supported structure was created and measured weights were added at known locations. This gave the information needed (modulus of elasticity and moment of inertia) to measure the forces and bending displacement to characterize the various dipole antenna materials and construction.

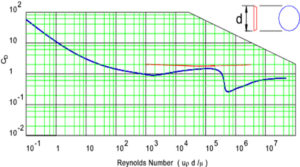

As the wind blows, the antenna deflects, which reduces the amount of projected surface area. The reduction of the surface area reduces the applied force on the bending of the antenna. Additionally, the geometry drag coefficient changes based on the flow. The measured testing data was analyzed in a circular iteration formula to solve the fluid-structure relationship to establish the maximum wind loading and related bending forces for high storm conditions.

Advertising Car Fin

Constructed a custom wind tunnel and force pull testing to measure the attachment forces for the magnetic and adhesive connections. Using the data of measured structural attachment strength and wind tunnel aerodynamic drag, the maximum safe road speed is determined for various orientation and mounting methods.